TWEETER MANUFACTURING

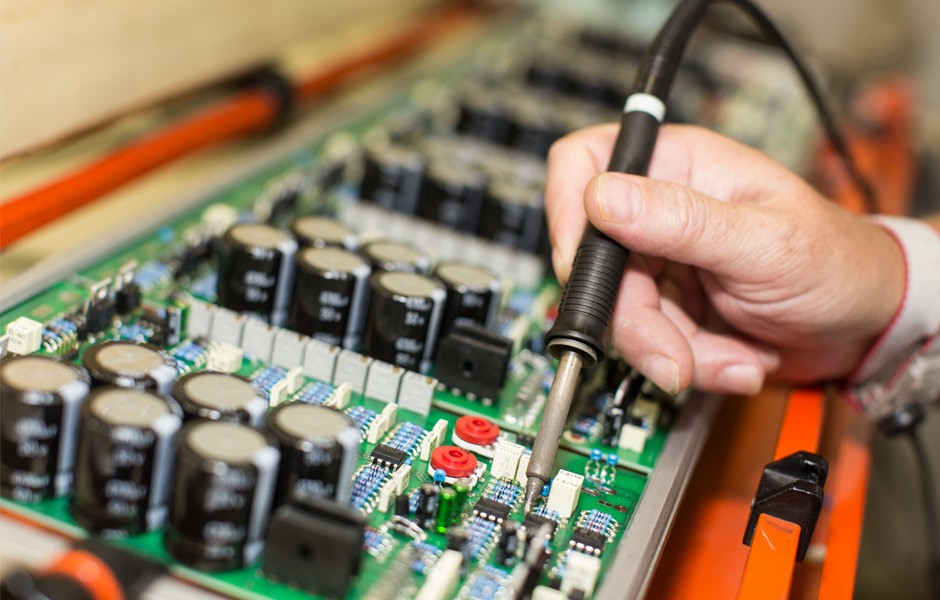

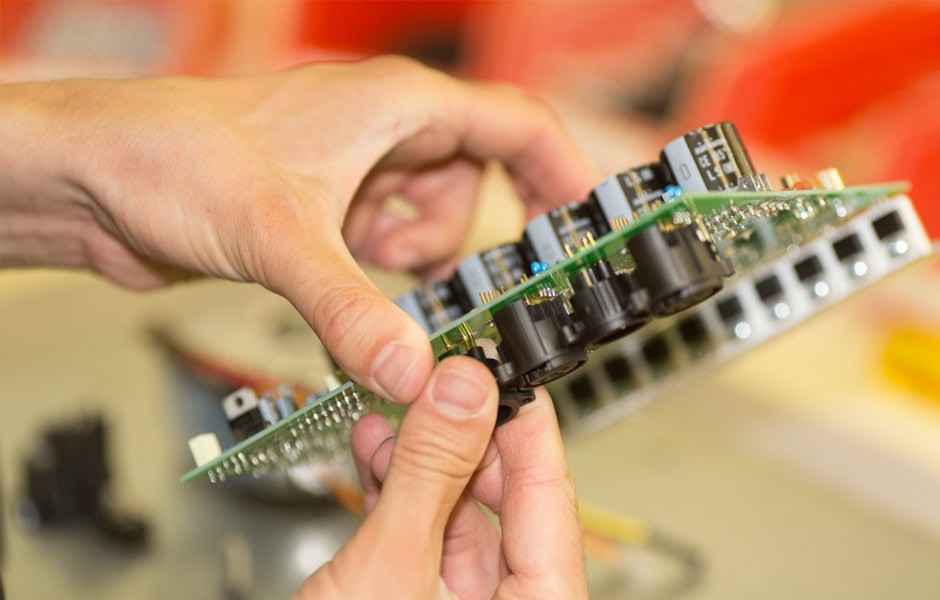

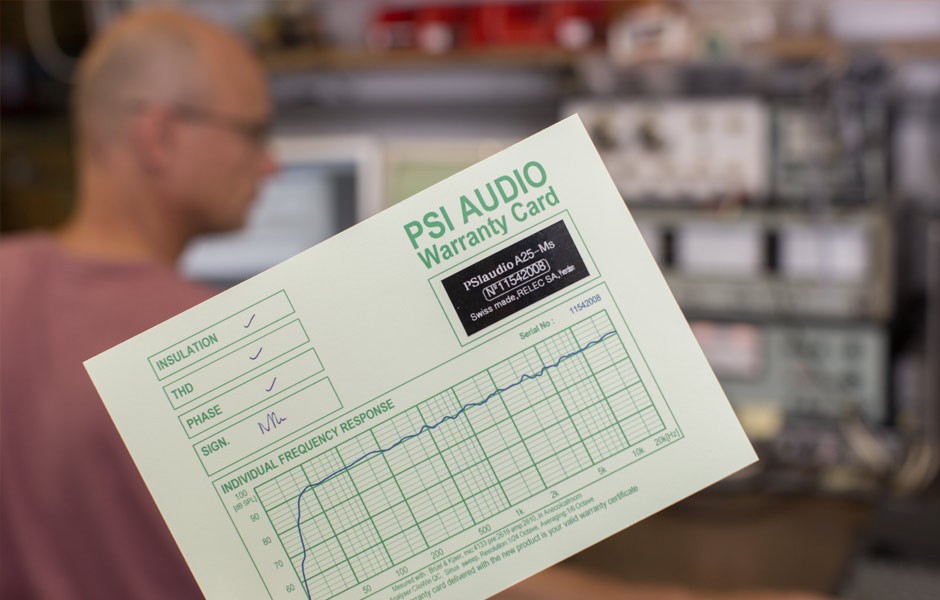

The tweeters of the A14-M, A23-M and A25-M are entirely designed and manufactured in our workshops to ensure the tightest tolerances in all aspects. Winding, magnetization, gluing and mechanical positioning using a microscope all need to be done by skilled hands to reach the record high SPL and low distortion required. A world record!